News & Articles

Browse all content by date.

A few days ago the CEO of the penny stock company Twin Metals announced that Antofagasta (its parent company) has decided against storing its toxic mine waste products at the PolyMet wet tailings lagoon facility in favor of a so-called “dry stacking” facility nearer its processing plant. It claimed that despite it being more expensive to do so (“dry stacking” is estimated by the industry to be 10 times more expensive to operate that a lagoon facility, so the promise may not be kept), it was “safer for the environment” than the inherently more dangerous wet tailings lagoon method.

Having had some personal and research experience with a certain “dry stacking” mining facility that wound up becoming an expensive Superfund site, I felt the need to comment.

Here is some of the evidence that I think that Minnesotans concerned about the long-term consequences of copper sulfide mining need to know.

(Note this column is a drastically shortened version of the 3500 word article that will be archived at: http://duluthreader.com/search?search_term=Duty+to+Warn&p=2)

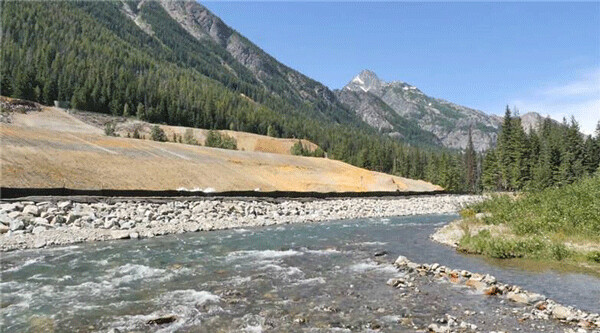

The photos in this column are from a helpful photo essay that was written by a journalist from www.mining.com that nicely illustrates some of the disastrous long-term consequences of a dry-stacking copper mining waste disposal facility that was used by a copper mining company in the 1930s. The company in question was the Canada-based Howe Sound Mining Company.

Howe Sound started extracting copper sulfide ore in the Cascade Mountains of eastern Washington State in 1938. The mine was called the Holden Mine, after James Henry Holden, the prospector who discovered the ore body in 1896. Howe Sound suddenly abandoned the enterprise after 18 years of extracting minerals at the site when copper prices tanked in 1957. Then, true to how most major corporations deal with their anonymous employees, fired all of its mine workers without compensation.

A few years later, Howe Sound tried to sell the abandoned mine site for $100,000, but it could find no buyers that wanted the albatross, so it gifted the remains of the operation to the Lutheran Church. The “gift” included the millions of tons of dusty toxic waste material on the opposite side of the creek from the village.

Several denominations of Lutherans collaborated in the establishment of a thriving year-round retreat center called Holden Village, which is only accessible via a 40-mile boat trip (taking up to 4 hours one way) up the 53-mile-long Lake Chelan. The final leg of the long trip to the village was a 12-mile long switch-back single lane road in an dilapidated old school bus.

My story comes into the picture because of the handful of times that I went to Holden retreats several decades ago. As we “villagers” arrived at the dock, I couldn’t help but wonder about the strange color of the clear, weed-less, minnow-less water at the dock site. I also naively wondered about how the fishing was there, but I never tried my luck in that lake.

My understanding about the strange color of the water gradually came into focus after becoming more aware of the serious long-term dangers of copper sulfide mining. What follows is more of what I have learned about the transnational mining corporations that have been steadily ruining the environment all across the world pretending to be largely providing (short-term) jobs, jobs, job to the regions that are ultimately heading toward (long-term) disaster

The Story of the Howe Sound’s Underground Mine,Dry Stacking and

SomeLessons for Northern Minnesotans

At the peak of production, the population of Holden Village, the Howe Sound company town that was located in the Cascade Mountain wilderness numbered about 600 (mostly miners and their young families). With the closure of the mine in 1957, all the employees and their families were displaced and had to move elsewhere. The miner’s homes were burned down, but the community buildings and the chalets of the company executives and management were preserved.

The company eventually dug 60 miles of deep tunnels in order to extract the sulfide ore.

During its 18-years of production, 10 million tons of sulfide ore were excavated. The ore was ground up into a fine powdery consistency and then processed into relatively pure copper and other metals. Those refined metals were then shipped down-lake and eventually to world markets, wherever the best prices could be obtained. During the war, most of the metals were purchased for use in Allied armaments industries.

A total of 212 million pounds of copper, 40 million pounds of zinc, 2 million ounces of silver, and 600,000 ounces of gold were produced from the 10 million tons of ore. 99% of the 10 million tons of powdery waste material still remain in Holden’s massive dump site in what is now euphemistically called by the mining industry “dry stacking”.

(Note: Sulfuric acid inevitably forms when pulverized sulfide-containing ore is exposed to water and oxygen).

For decades, this toxic mine water has been over-flowing the mine portal into a river that flows into Lake Chelan and eventually into the Columbia River.

In the 1930s, dry stacking was the norm for mining companies as their method of disposal of the permanently toxic tailings – which happens to be exactly what Antofagasta/Twin Metals recently announced that it was planning to use at its controversial, not-yet-approved mine site, which is immediately adjacent to the pristine Boundary Waters Canoe Area Wilderness (BWCA), which is contiguous with Canada’s equally pristine Quetico Provincial Park.

Superfund Sites are not Good for any State, Especially Northern Minnesota

The dry tailings dump and the abandoned underground mine at Holden Village was designated a toxic Superfund site in the late 1980s by the US Environmental Protection Agency (EPA). But remediation was not begun until decades later.

But for the entire 70 years of its existence, the “dry stacking” tailings dump at Holden has been polluting the area’s ground and surface water (and the air as well).

Does “Dry Stacking” of Copper Sulfide Mine Waste Decrease Pollution

or Increase it?

“Dry stacking” of toxic powdery uncovered tailings that blow around with the wind will create air pollution that wet tailings lagoons won’t, but the tailings could make downstream water pollution more likely in the short term - compared to the “wet” tailings lagoons that use soluble, earthen-walled dams that, under ideal conditions, hold back the equally toxic, water-logged, “slurried” tailings.

It all depends on the rainfall of course – unless and until the earthen dam of the lagoon dissolves or collapses “for unknown reasons”.

The Story of Rio Tinto – the Corporation and the River

Rio Tinto, the huge UK-based transnational mining corporation that eventually became legally responsible for “remediating” Holden’s Superfund site, is infamous for the massive amount of damage that its copper sulfide mining operations have done to southwestern Spain. The acid mine drainage into the Rio Tinto river estuary from the copper mine tailings has resulted in total and permanent poisoning of the downstream area for over a century, even before open pit mining with giant earth-moving equipment made it feasible to mine low-grade copper sulfide ore. Most of Spain’s Rio Tinto river has a pH as low as 2.0 (!!) because of the sulfuric acid that is formed when small chunks of sulfide ore are exposed to oxygen and water. That highly acidic water then is capable of dissolving and oxidizing iron that is in the tailings, which turns iron into iron oxide - which is another name for rust. Hence the red color of the acidic river water.

Copper Sulfide Mining is NOT Necessarily Good for Jobs – or Fishing

The acid mine-polluted water in the Rio Tinto river has also seriously contaminated the once fertile (and now barren) fisheries where the river flowed into the Gulf of Cadiz (near the Strait of Gibraltar). The same can be said for Railroad Creek and Lake Chelan.

Temporary jobs that were created by the Spanish copper mining industry meant the permanent loss of jobs in the once-thriving Spanish fishing industry. The same could be said for the loss of a once-productive sport fishing industry in Lake Chelan.

The Holden Mine clean-up costs to Rio Tinto (the mining conglomerate) has so far amounted to $200,000,000 - and counting. The money spent in the multi-year effort has been mainly for the following construction projects:

1) a new road leading from Lake Chelan to the mine site that can transport heavy equipment;

2) a newly-excavated river bed so that Railroad Creek will be farther away from the tailings;

3) a barrier to stem the flow of toxic, highly acidified water from spilling out of the mine portal;

4) a permanent water treatment plant that ideally will purify a portion of the ground and surface water that drains from the intermittently-wet “dry”, newly-walled tailings dump;

5) a deep trench (all the way down to bedrock as far as 90 feet down!) that was then filled with material that allowed a new impervious wall to be built upon it to prevent the dry tailings from entering the creek (presumably made of concrete);

6) etc.

Does an Un-walled, Dry-stacked Tailings Dump Become a Dangerous Wet Tailings Lagoon When it is Walled-in?

The fact that a wall has been built around a previously un-walled “dry-stacked” tailings mound/dump during Superfund remediation efforts technically makes it an inherently more dangerous “wet” tailings facility that could, at some future catastrophic weather event, contain large volumes of rain that could catastrophically overflow the walls. In the case of the Holden site, where 300-inch snow falls occur during most winters, a sudden snow melt during a warm spring could still potentially overflow into the nearby river.

Northern Minnesotans are facing the threat of having profiteering, sociopathic (sometimes criminal), transnational foreign mining corporations come into the unpolluted parts of our state and damage all aspects of our region.

These corporations will inevitably use up tremendous amounts of fossil fuel, electricity and other resources. They will threaten our sport fishing industry, existentially threaten the dozen downstream St Louis River towns, and pollute a lot of water, air and soil. Minnesota’s irreplaceable mineral resources will then be sold on the world markets to whatever entity, whether war-monger, dictator or criminal corporation that makes the highest bid for the product.

Minnesotans need to better understand the complexity of Superfund projects like the one that occurred at Holden Village and may occur in Minnesota – probably at a time in the future when our children and grandchildren will have to contend with the issue – if there is a functioning EPA still in existence by then.

Here is the link of an informative 10-minute interview of the Holden Superfund project director: https://www.epa.gov/enforcement/case-summary-epa-and-forest-service-issue-uao-holden-mine-site

What Lessons does the Holden Superfund Project hold for Northern Minnesotans?

The recent Antofagasta announcement comes from a company that always uses wet-tailings storage lagoons for its inevitably toxic mine wastes. Therefore, the Twin Metals “dry stacking” waste disposal project will necessarily be experimental for them.

The announcement also represents an admission by the corporation of how valid are the vigorous oppositions to copper mining in water-rich Minnesota.

The logical reasons for such opposition have been consistently articulated by knowledgeable, un-biased, well-informed citizens and the variety of pro-environment/pro-safe water organizations of which they are members.

There are many entities that are opposing the experimental plans of the Canadian penny stock company PolyMet (and its criminally-indicted parent corporation Glencore) to extract and process low-grade copper ore in northern Minnesota.

The many logical points that have been made by these opponents have been repeatedly (and very weakly) refuted by the many well-publicized dis-information campaigns, illogical letters to the editor from mining industry shills who have hidden conflicts of interest that are usually not revealed.

Much of the illogical pro-copper mining rhetoric comes from our so-called political, industrial and media “leaders” that refuse to consider the potential, catastrophic environmental risks to the St Louis River and Lake Superior, not to mention the threats to the survival of the dozen river towns that are downstream from the massive tailings lagoon at Hoyt Lakes.

It is important to be reminded that the proposed PolyMet tailings lagoon (projected to rise to a height of 270 feet!) is located at the headwaters of the St Louis River that empties into Lake Superior.

In its statement of intent to use an experimental “dry stacking” method of tailings storage, Antofagasta is thus acknowledging that PolyMet’s 270-foot tall earthen dam cannot be expected to safely hold back the toxic slurry for an eternity. One can be sure that Antofagasta doesn’t want to be part of a trillion-dollar lawsuit if and when the lagoon collapses.

Hence their disingenuous statement reveals that the company doesn’t want to be associated with the dangerous PolyMet project.

Both mining corporations are fully aware of the deadly, catastrophic tailings lagoon collapses in Brazil, British Colombia and elsewhere. Here are five links to learn more about those disasters:

1) A recent Duty to Warn column about three recent mine disasters: http://duluthreader.com/articles/2019/02/07/15982_how_to_destroy_a_river_and_create_an_environmental

2) A 5 minute video of the 1-25-2019 Brazilian mine disaster: https://www.youtube.com/watch?v=eGaQ0vjHZE0

3) This video shows the first horrifying – and instructive - minute of the 1-25-2019 Brazilian mine disaster that killed several hundred people, displaced thousands more and devastated the lives of tens of thousands of others: https:/www.youtube.com/watch?v=a0qf5AuF3gw

4) This video is also about the 11-15-2015 Brazilian mine disaster: https://www.youtube.com/watch?v=k0PWRiEWMTY

5) The first 6 minutes of this 25-minute video is about the aftermath of the 2015 Brazil mine disaster that killed many downstream mining family members and displaced 6,000 residents of downstream villages: https://www.youtube.com/watch?v=E3oGMJHvtaM

If Antofagasta somehow obtains permits to mine copper near the BWCA, either from the Trump administration’s pro-mining/anti-environmental EPA, from Minnesota’s PCA (Pollution Control Agency) or from Minnesota’s DNR (Department of Natural Resources), the placement of a $200,000,000 escrow account needs to be a requirement for both PolyMet and Twin Metals, so there will be no argument about who pays for the cleanup when their projects become Superfund sites.

Dealing with Disinformation Campaigns from our Political, Media and Industry “Leadership”

One hopes that nobody with any political or media influence in northern Minnesota is falling for the propaganda efforts of Antofagasta, Glencore or any other transnational corporation, whether it be in industries representing Big Mining, Big Pharma, Big Vaccine, Big Medicine, Big Defense, Big Politics, Big Aerospace, Big Media, Big Chemistry, Big Agribusiness. Big Banking, Big Insurance, Big Technology, Big Oil, Big Coal, or any greedy, profiteering Big Business that has the Big Bucks to propagandize/brainwash our dupable, co-opted politicians and media elites (and our naïve selves, as well) into supporting (or purchasing) something that may turn out to be more expensive, destructive or lethal in the long-term.

For additional information on the Holden Mine Superfund and Acid Mine Drainage realities that makes copper/nickel mining far more toxic than iron mining, go to: https://www.epa.gov/enforcement/case-summary-epa-and-forest-service-issue-uao-holden-mine-site At that link will be found this information:

“For info on ARD (Acid Rock Drainage) check out the Global Acid Rock Drainage Guide (www.gardguide.com). It's aimed at practitioners but should also be accessible to people wanting to know more. In a nutshell - an ARD "source" as you call it, are the naturally occurring sulphides in the rock material that has been moved by the mining process and exposed the atmosphere (can be waste rock, tailings or the walls of pits or underground stopes/adits). The sulphides oxidize in the presence of oxygen and create a leachate that has a low pH and can also be high in metals (depending on the rock types). Once the oxidation process has started, there is no stopping it - only slowing it, by reducing the amount of water infiltrating the material. Current best practice refers to acid and metalliferous drainage (AMD) as sometimes the leachate is not acid but is still high in metals. Anyway, it is difficult and costly to remediate. These days it's much better to not allow the process to begin, but back in 1950s they would hardly been aware that it was an issue. This is a simple explanation, the Global Acid Rock Drainage Guide (GARD Guide) has all the details if you would like more.”

Photos of a remote $200-million mine cleanup in Washington State

By Michael Allan McCrae - August 19, 2014

The Holden Mine clean-up is a remediation project costing upwards of a $200 million at a remote access site in central Washington State to fix environmental damage from an underground copper mine that operated over 50 years ago.

Due to the former mine dumping tailings and waste rock on wetlands and near a creek, the U.S. Environmental Protection Agency was prompted to declare the closed mine a Superfund site in the late 1980s. Intalco was responsible for remediating the mine site. Intalco is a successor to the Howe Sound Company.

The federally-mandated cleanup is addressing the following issues:

Snowmelt and rainwater mix with metals to create acid mine drainage from mine portal, and acid rock drainage (ARD) from tailings and waste rock piles.

ARD affects groundwater and surface water quality, including in Railroad Creek.

While creek water is safe for human consumption downstream of Holden Village, it contains concentrations of hazardous substances that exceed water quality standards for aquatic life.

Slopes of tailings piles are too steep to withstand a large earthquake.

Rio Tinto estimates that there will be 370 jobs created over the life of the project, 60% being local. There will also be $30 million in local economic benefits.

NOTE: The views expressed here are those of the author and do not necessarily represent or reflect the views of Reader Weekly.”

| Tweet |